YBS SuperQuilt Insulation 1.5m x 10m

- Description

- How-To Video

- How-To Guides

- Reviews

- Specification

- question_answer Q&As

- picture_as_pdf Data Sheets

The Ultimate Multifoil Insulation

YBS SuperQuilt Multifoil Insulation – The highest performing EN Certified Multifoil Insulation on the market.

SuperQuilt is exclusively the only multifoil product with True Aluminium Foils as outer layers. Inferior products such as SuperFOIL & TLX use look-lookalike plastic foils which hold little reflective benefits.

This product has True Aluminium Foils as outer layers which provide better reflective properties. The Foil also improves rigidity and most importantly, creates a flame-proof layer!

Next-Day Delivery Nationwide!

SuperQuilt is manufactured in the UK and has been independently tested to the latest industry standards.

Insulation Properties

Layers: 19

Thickness: 40mm (7mm Compressed)

Width: 1.5m (1.2m width also available)

Length: 10m

Coverage: 15m² (12m² also available)

Weight: 900g per m²

Foil Emissivity: 0.02

Water Vapour Resistance: 1569MNs/g

Going through building regulations, for your project? Visit our Free & Instant Online U-value Calculator. We have over 1,000 solutions available for Roofs, Walls, Ceilings, and Floors!

Can be used to meet U Values

See how you can use SuperQuilt in your next project to meet Building Regulations. You can use our free and instant Online U-Value Calculator. Or, if you would prefer to speak through your project – request a ‘Call Me Back’ and one of our dedicated team members will call you back within the hour.

Ordering Bulk?

The most cost-effective way to order SuperQuilt, if you require 9 or more rolls is to purchase our Trade Pallet Deals which also include ancillary items you will need for your project ThermaSeal Foil Joining Tape and a Heavy Duty Staple Gun including 5,000 x 14mm Staples.

Insulation Certification Details;

Below are all the solutions YBS SuperQuilt is certified for (LABC & BDA). Links below will provide further technical information, fixing instructions, and typical U-values that can be achieved;

- Pitched Roof Details – See Link

- Flat Roof Details – See Link

- Re-Roofing Systems – See Link

- Timber Frame Wall Systems – See Link

- Dry Lining Wall Details – See Link

- External Wall Insulation Details – See Link

- Suspended Timber Floor Details – See Link

- Solid/Floating Floor Details – See Link

- Crawl Space Floor Details – See Link

Delivery Schedule;

Order before 2 pm Monday – Friday, and receive your delivery the next working day delivery (UK Mainland)

Orders placed after 2 pm Friday, or over the weekend, are delivered Tuesday. (UK Mainland)

Discounted pallet rates are also available throughout Europe.

If you would prefer to place your order via phone – Feel free to request a Call Me Back and one of our helpful team, will call you within 60 minutes.

FREE GIFT

Spend £500 + VAT and Choose a FREE GIFT at the checkout!

Free Gifts Include: Thermaseal Foil Joining Tape, a Heavy Duty Staple Gun Kit, Multifoil Insulation Scissors, or Thermaseal Double-Sided Tape.

How to Insulate your Loft using a Double Layer of SuperQuilt

How To Insulate Your Walls using SuperQuilt

Triple Layer 0.18 Re-Roof System

How to install SuperQuilt Insulation on a Flat Roof to meet Building Regulations

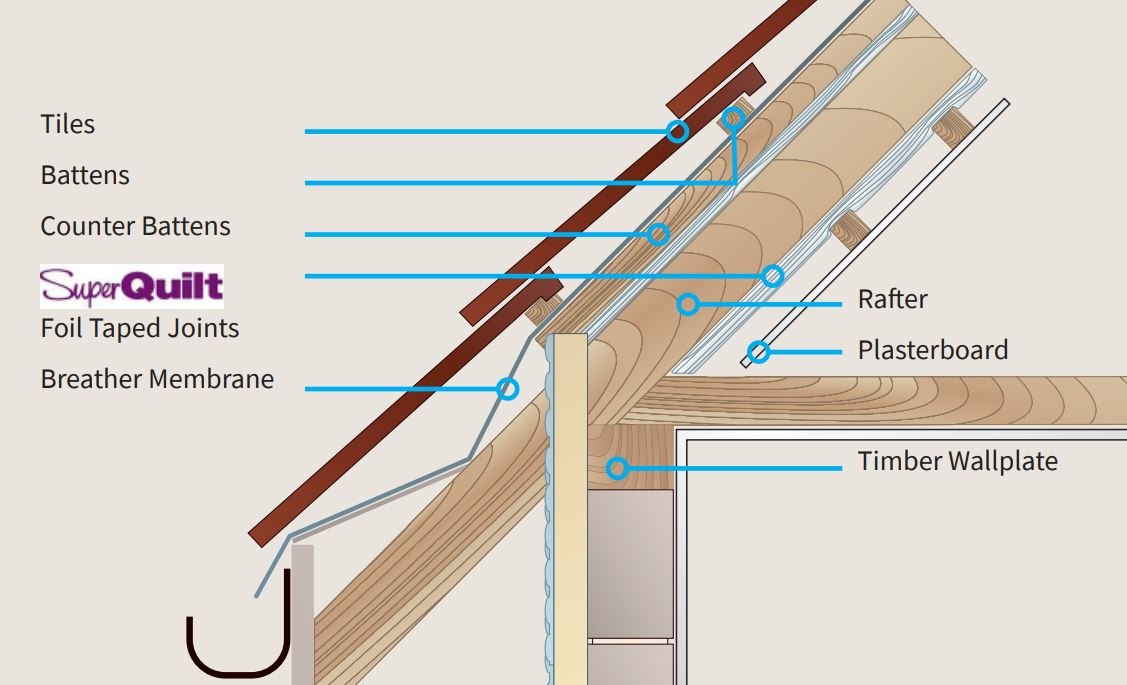

How to Fit SuperQuilt Under Rafter

-

Installing first run of SuperQuilt

SuperQuilt can be installed either vertically or horizontally, dependent on rafter height. Staple SuperQuilt to the rafters at spacing's of approx 300mm. Ensure SuperQuilt is pulled taught whilst rolling and stapling.

-

Overlaps & Tapes

Ensure all SuperQuilt Insulation joints are overlapped by min 50mm. Ensure overlaps are fully taped and sealed using Thermaseal Foil Joining Tape. SuperQuilt can be easily cut using Multifoil Scissors or a Cutting Knife - Both available in our Multifoil Fitting Kit.

-

Eaves Detailing

At the eaves, SuperQuilt is cut around the rafters, and sealed to the cavity wall insulation or wall plate. It is vital to ensure fully taped and sealed, to ensure that an airtight envelope is created

-

Counter Batten

Fix 25mm x 38mm battens at right angles to the rafters. Deeper battens can be used if preferred. Battens also must be fixed around the perimeter of windows.

-

Internal Finish

The plasterboard is then screwed into the battens in the usual manner. When SuperQuilt is installed as the most internal insulation layer, there is no requirement for a foiled-back plasterboard. SuperQuilt will work as a high performing Vapour Control Layer, when taped and sealed using Thermaseal Foil Tape.

How to Fit SuperQuilt onto Solid Walls

-

Install Timber Battens

Start by installing treated timber battens directly onto your solid walls. We advise the spacing's to be between 400mm & 600mm centres. Usually the thickness of the battens required are 25mm however this will depend on your desired U-value. To find the recommended batten depth for your project, visit our Free to use Online U-value Calculator.

-

Staple SuperQuilt

Next, staple SuperQuilt onto the first set of battens, then roll out SuperQuilt horizontally. We recommend the use of 14mm staples when fixing SuperQuilt. Multifoil-Insulation's Fitting Kit includes a Heavy Duty Staple Gun & 5,000 14mm Staples. SuperQuilt can be easily cut using our Multifoil Scissors, available on our website.

-

Overlaps & Sealing

Overlap SuperQuilt by a minimum overlap of 50mm. Tape and Seal SuperQuilt using ThermaSeal Foil Tape. We recommend sealing all overlaps, joints and the perimeter to ensure a complete seal. This will eliminate the risk of condensation.

-

Install Counter Battens

Once SuperQuilt is fully installed and covered, install counter battens over SuperQuilt. We recommend to create a frame around any windows, and around the perimeter. Thickness of batten will depend on desired U-value. To find the recommended batten depth for your project, visit our Free to use Online U-value Calculator.

-

Installing Plasterboard

The plasterboard is then screwed into the battens in the usual manner. When SuperQuilt is installed as the most internal insulation layer, there is no requirement for a foiled-back plasterboard. SuperQuilt will work as a high performing Vapour Control Layer, when taped and sealed using Thermaseal Foil Tape. Optional Insulated Plasterboard's can be used for extra thermal benefits and to reach a lower U-Value.

How to Insulate Above a Concrete Floor Using SuperQuilt

-

Installing first run of SuperQuilt

SuperQuilt can be rolled out vertically or horizontally along the concrete floor. Leave enough material at the edges to protrude SuperQuilt Insulation above the floor deck. Ensure the concrete floor is fully clean, flat, and debris free.

-

Joints and Taping

Ensure SuperQuilt is butt jointed with other layers on both the verticals and horizontals. Fully tape and seal all butt joists of SuperQuilt with Thermaseal 75mm Foil Joining Tape.

-

Installing Battens

Timber battens or joists are then laid over the top of SuperQuilt. Ensure the timbers are spaced evenly to suit the particular flooring. SuperQuilt will compress to around 7mm when timber is installed above. We recommend min depth battens of 50mm, using 75 or 100mm joists/battens will give greater thermal benefits.

-

Finish with Flooring

Proceed with installing your timber boarding floor. The deck is then fixed at 200mm centres, with 37mm screws into the joists or battens below

How to Insulate Your Roof Without Any Kingspan or Celotex

-

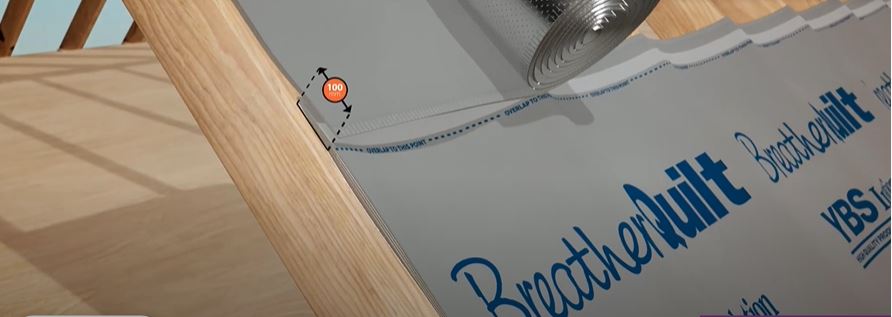

Install your first layer of BreatherQuilt

Firstly, install BreatherQuilt Insulation on the external of your pitched roof. The reflective foil will need to be facing inwards. Begin at the bottom of your rafters. Staple BreatherQuilt to the first rafter, using 14mm staples (Max 300mm spacing). Roll BreatherQuilt horizontally across each rafter, stapling continuously to ensure the product is secured. BreatherQuilt should sag between the rafters as opposed to being pulled taught. Ensure that once the tile battens are installed, there is a clear 10mm gap between the top layer of BreatherQuilt and the tile battens.

-

Install next run(s) of BreatherQuilt

Install the next layers of breatherquilt, ensure that you overlap the product by 100mm. Use the Double Sided Tape that is already on the breatherquilt to secure the two runs and then staple as you did before. Repeat this process as many times as needed, dependent on how many runs are required for the roof. Additional rolls on the verticals should be butt jointed on the rafters. Ensure the butt jointed rolls are stapled as previous and taped using waterproof tape.

-

Install Tile Battens & Tiles

At the eaves, BreatherQuilt should extend onto a suitable eaves carrier. This works in the same method as standard breather membranes. Proceed next by installing horizontal tile battens, on the top of the BreatherQuilt. Finally, finish by install tiles or slates.

-

Install the first layer of SuperQuilt

The two layers of SuperQuilt should now be installed on the internal. By internal we are referring to the underside of the roof rafters. The first layer of SuperQuilt is to be recessed in-between the rafters (as per image) Recess by 25mm) and fixed with staples on to the battens. The material is then pulled taught and fixed to the opposite rafter. Tape and seal the first layer, over the laps and around the perimeter.

-

Install the second layer of SuperQuilt

Once the first has been installed then you can now install the 2nd SuperQuilt layer. Staple or nail the second layer through the first layer into the rafters behind. Ensure this layer is also pulled taught, there will then be a cavity between the two layers of SuperQuilt. As per the first layer, the second layer is also overlapped by 50mm. Ensure again the product is fully taped and sealed using Thermaseal Foil Joining Tape.

-

Apply a layer of Timber Battens

Apply a layer of timber battens, leaving at least 400mm between each one. The battens should be 25mm in depth min, to enable the Superquilt to reflect and perform.

-

Internal Finishing

Once both layers are installed and taped, you are ready for your batten & plasterboard. Start by installing min 25mm battens on the insulation. We advise to cross-batten, however vertical battens can be used. Finish by installing 12.5mm Plasterboard. There is no requirement for a Foiled-back plasterboard or VCL. SuperQuilt works as a high performance Vapour Control Layer when taped and sealed.

| Length | 10m |

| Width | 1.5m |

| Thickness | 40mm |

| Coverage | 15m² |

| Layers | 19 |

| Weight | 12.5KG |

| Core R-value | 1.52m²K/W |

| Roof R-value | 2.50m²K/W |

| Wall R-value | 3.00m²K/W |

| Floor R-value | up to 5.56m²K/W |

| Foil Emissivity | 0.02 |

| Water Vapour Resistance | 1569MNs/g |

What does SuperQuilt consist of?

SuperQuilt consists of 19 itch-free layers including True Aluminium Foils as the Outer and Inner layer. The other 17 layers consists of recycled waddings, PE Foams, and other reflective foils.

Is SuperQuilt harmful?

SuperQuilt contains no harmful fibres and does not release any toxic gasses when cut or installed. When installing SuperQuilt, there is no requirement for any masks, PPE or gloves.

What thickness is SuperQuilt?

SuperQuilt is available in just one thickness, which is 40mm at a relaxed thickness and will compress down to 7mm.

Do SuperQuilt require airgaps?

To gain the best thermal performance, we recommend a minimum cavity/batten of 25mm both sides of the insulation. This is to allow the product to expand and reflect. If a cavity is removed, the performance would reduce by approx 20%.

Is SuperQuilt fireproof?

SuperQuilt has a Class E Euro Fire Classification Certificate. SuperQuilt is not fully fire-proof, however the true aluminium outer layers are flame proof, meaning if a naked flame touches the product, it will smoulder as opposed to spreading.

What’s the difference between SuperQuilt and SuperFoil?

SuperQuilt is a premium product with true aluminium foils as the outer layers, compared to SuperFoil’s range which has metalized foils which provides a lower Fire Classification Grade (Fail) SuperQuilt is also fully certified, and UK manufactured compared to SuperFoil.

Does SuperQuilt achieve building regulations?

In some applications SuperQuilt will achieve building regulations stand-alone. In Roofs and Walls, you may need to use additional insulation alongside SuperQuilt to achieve your desired U-value.

Can SuperQuilt be used on External side of Walls?

SuperQuilt is suitable for insulating on both the internal and external of solid walls. Please ensure there is a min batten of 25mm both sides of the insulation.

How To Video

Key Features

- UK Manufactured

- LABC, BBA & BDA Certified

- Flexible, Thin & Easy to Install.

- Proven to Save Cost & Space

- High Performing Vapour Control Layer

- Suitable for New Builds & Refurbs

- True Aluminium Outer Layers

- Made from 83% Recycled Materials

- Roof R-value – 2.5m²K/W

- Wall R-value – 3.0m²K/W

- Floor R-value – 4.45m²K/W

Fast Next Working Day Delivery

Fast Next Working Day Delivery Bulk Discounts Available

Bulk Discounts Available Order Pre 2pm for Delivery

Order Pre 2pm for Delivery

There are no reviews yet.